Understanding what factors determine pricing can be challenging when it comes to CNC machining. How is it that two identical parts with similar dimensions and material come with such different prices tags? Well, there are multiple factors contributing to CNC machining costs; here are a few key ones you should keep in mind when pricing CNC services:

- Materials Selection: Your selection of material affects machining costs in two ways: raw material costs and machineability. Certain materials are more costly as raw materials while some can be harder to work with, increasing overall machining expenses. Select an affordable yet easily machineable material to meet design requirements for maximum cost effectiveness and profitability.

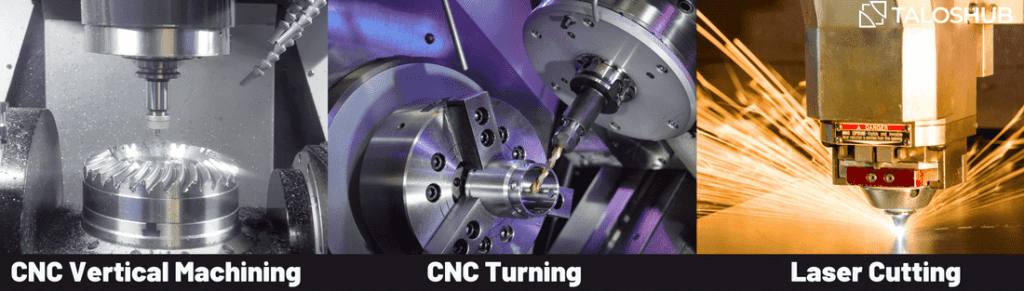

- Part Geometry: Complex parts with intricate designs tend to be more costly to produce. Multiple machining operations will increase both costs and time needed to produce these parts; for instance, ordering something that must first be turned on a lathe before being transferred over to a milling machine will cost more.

- Part Size and Geometry: When pricing machining services, part size and geometry play a critical role. Larger parts often require more material at higher material costs; also, larger parts often take longer to be machined than their counterparts.

- Finishing Operations: Machined products often require additional finishing operations such as surface finishing, heat treatment, special processes and coatings to reach their potential. Each of these adds costs and should be assessed carefully to determine necessity and value.

- Part Quantity: Ordering multiple quantities at once helps improve production efficiency and lower unit costs by spreading costs like CAM programming, setup time, material costs and specific fixtures/tooling necessary for producing one designed part among multiple units purchased at once – thus lowering per part prices.

- Part Tolerances: Tight tolerances have an enormous effect on overall costs, especially those related to manufacturing parts. Looser tolerances tend to result in cheaper parts. If tight tolerances are necessary, even slight relaxation in tolerance can decrease costs; novice engineers often unnecessarily increase costs by showing excessive tolerance on their parts.

- Part Design/Small Features: When considering part design, small features play an essential role in machining costs. Processing smaller features takes more time and machine time, which increases overall costs. If these small features are unnecessary to the functionality of your part, consider eliminating or minimizing them as soon as possible. Also keep the following aspects of part design in mind:

- Thin Walls: CNC-machined parts with thin walls tend to be more expensive due to their reduced speed of machining and potential tolerance issues that make keeping tolerances manageable more challenging. To minimize costs associated with thin walls machining costs, the minimum thickness should be set at 1/32″ (0.794 mm).

- Internal Radii: Internal radii have an important impact on machining time. A CNC machining tool’s natural action is to leave rounded corners inside corners; as their radius increases, the tool requires fewer passes to remove material, leading to faster machining. On the other hand, tight internal corner radiuses necessitate smaller tools moving at slower speeds which increases machining time significantly.

- Deep Pockets/Holes: Producing parts featuring deep pockets or internal cavities often requires time-consuming and expensive production processes. Such designs challenge machine rigidity, require special tooling solutions, and may lead to tool breakage; any depth greater than 5 times your tool diameter should be avoided for best results.

- Rounded Surfaces: Undercuts such as O-ring or dovetail grooves can be costly to machine. Custom-made tooling and slower cutting feeds often increase costs of making such parts, so discuss them with your machining shop in order to find an economically beneficial undercut design.

- Thin Walls: Machining CNC parts with thin walls tends to be more costly as their reduced machining speeds cause deviations that make tolerance holding more challenging. To reduce costs while keeping tolerances consistent, minimum wall thickness should be 1/32″ (0.794 mm).

- Internal Radii: Internal radii can have a significant impact on machining time. A CNC machining tool naturally leaves rounded corners inside corners, so as its radius increases it needs fewer passes to remove material, leading to more efficient machining. On the other hand, tight internal corner radius requires smaller tools that move at slower speeds, lengthening machining times.

- Deep Pockets/Holes: Parts containing deep pockets or internal cavities require time-intensive and costly production processes, posing rigidity challenges to machines, special tooling needs and are more susceptible to tool breakage than those without. Aim for depths no greater than five times your tool diameter as this will help ensure accurate tool production.

- Rounded Surfaces: Machining undercuts such as O-ring grooves or dovetail grooves can be costly to produce. They often require custom tooling and slower cutting feed rates that increase part costs significantly. Discuss your undercut requirements with your machining shop to achieve the most cost-effective undercut design possible.

Text: Remove text from your part unless it is necessary and cost-effective to embed it within its final product.

Conclusion – As previously outlined, these factors have an immense effect on the cost of machined parts, and being aware of them during early development stages can help you understand which costs influencers exist and reduce overall project expenses.

However, it’s essential not to compromise the integrity of your parts in order to save money. Key features that contribute to their design shouldn’t be removed for cost savings alone.

At Taloshub, we take great pride in our dedication to engineering innovation that reduces machining costs for our customers. By harnessing cutting-edge technologies and continuously refining our processes, we provide cost-effective solutions without compromising quality.

Taloshub offers precision CNC machining services at competitive pricing, and with high-quality results. Reach out to us now with your design specifications and quantities at order@taloshub.com, and our team will promptly provide an in-depth quote that meets all of these criteria.

Optimizing part design, selecting appropriate materials, considering tolerances and taking advantage of economies of scale are all integral parts of minimizing machining costs. Let Taloshub be your trusted partner in turning your designs into reality while maximising cost efficiency.

Taloshub offers CNC machining services that combine innovation, engineering excellence and competitive pricing – we look forward to partnering with you on your next project!

Keywords: CNC Machining, Machining Costs, Material Selection, Part Geometry Size Finishing operations Quantity Tolerance Design Cost Optimization Taloshub Innovative Machining Engineering Excellence.