Taloshub’s 3D Printing Technology: Unveiling the Future of Additive Manufacturing

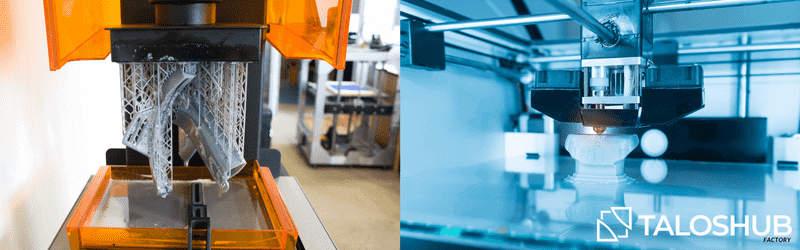

As an industry pioneer in additive manufacturing, Taloshub utilizes cutting-edge 3D printing technology to push the envelope. Our comprehensive suite of printing processes combined with an expansive selection of materials enables us to deliver extraordinary results across a wide variety of applications. Let’s delve deeper into our 3D printing capabilities:

- Prototyping FDM (Fused Deposition Modeling):

-

- This process utilizes thermoplastic filament that is extruded layer by layer to form three-dimensional objects.

- Taloshub’s FDM printers achieve unparalleled accuracy, making form-fit prototyping fast and cost-effective as well as producing jigs and fixtures a reality.

- Materials such as PLA, ABS, ASA, PETG and TPU offer considerable versatility in terms of mechanical properties, temperature resistance and durability.

- Industrial FDM:

-

- Taloshub’s industrial-grade FDM printers produce reliable and high-performance parts ideal for functional prototypes and short run production runs.

- At 3D Manufacturing Works, we utilize cutting-edge materials like ULTEM 9085, ULTEM 1010, ABS M30 and ABSPlus as well as PA 6 Stratasys PC Stratasys and Markforged Onyx that possess exceptional strength, heat resistance and chemical resistance properties.

- Industrial FDM ensures both precision and durability to meet the rigorous demands of various industries.

- Prototyping SLA (Stereolithography):

-

- Taloshub’s SLA process uses liquid resin that is selectively cured using UV laser technology to produce highly detailed visual prototypes with impeccable precision and surface finish.

- Formlabs resin materials such as Grey Pro Resin, Clear Resin, Durable Resin, High Temp Resin, Standard Resin, Tough Resin 2000 Rigid Resin 4000 and Flexible Resin 80A enable us to produce intricate geometries and stunning visual models.

- Taloshub’s expertise in SLA ensures prototypes that accurately represent the final product, aiding design validation and highlighting aesthetics.

- Industrial SLA:

-

- Taloshub’s Industrial SLA process excels at producing highly detailed functional prototypes and master patterns for casting applications.

- Materials such as Accura 25, Accura 60, and Accura Xtreme White 200 exhibit superior mechanical properties, high accuracy, and excellent surface finish.

- Industrial SLA processes are well known for producing intricate yet durable parts that withstand functional testing, acting as reliable patterns for casting processes.

- SLS (Selective Laser Sintering):

-

- Taloshub’s Selective Laser Sintering (SLS) technology utilizes a high-powered laser to combine powdered materials such as PA 12 and Glass-filled PA 12, into solid objects layer by layer.

- This process makes possible the creation of functional prototypes and low-run production parts with excellent mechanical properties, including strength, toughness, heat and chemical resistance.

- SLS printing is ideal for complex geometries as it eliminates the need for support structures during printing.

- MJF (Multi Jet Fusion):

-

- Taloshub’s Multi Jet Fusion process leverages HP’s cutting-edge Multi Jet Fusion technology for fast and cost-effective production of functional prototypes and low-run production parts.

- MJF uses HP PA 12 and Glass-filled HP PA12 materials to deliver superior part quality, intricate details, and consistent mechanical properties.

- Taloshub’s use of MJF allows them to produce parts with outstanding surface finish, isotropic strength and dimensional accuracy.

At Taloshub, our focus on optimizing and continuously improving our 3D printing processes to meet the highest standards for quality and precision is of utmost importance. Our knowledgeable team of technicians and engineers closely oversee each step in our printing process for maximum effectiveness.

From file preparation to postprocessing, our focus on exceptional results ensures we deliver exceptional 3D printed objects. Below are technical specifications outlining key details about each of our 3D printing methods:

FDM printers feature minimum wall thickness requirements of 0.8 mm and layer height ranges of 100-300 mm for optimal layer height performance, as well as maximum build sizes up to 500x 500x 500 mm and tolerances up to +-0.5% with lower limits set at +/0.5mm (+0.020″).

SLA technology features:

– Minimum wall thickness of 0.5 mm 50 to 100mmepaisseur With SLA:

Maximum build size 145x145x175 mm Tolerances +-0.5%, lower limit 0.15mm (+0.006″)

Use of SLS:

:

Minimum wall thickness of 0.7mm: Layer Height 100mmMaximum Build Size 420x500x420mm Tolerances are +/-0.3% with lower limit tolerances +/-0.3mm (+0.012″).

And finally with MJF:

The minimum wall thickness : 7.7mm whilst layer height should not go below 80 um; maximum build size being 380x285x380mm and tolerance +/- 3.3% as the lower limit (+/-o.o12″).

At Taloshub, our commitment to excellence extends beyond technical aspects. We hold firm values when it comes to sustainability and eco conscious practices that ensure responsible manufacturing practices. In order to be mindful of waste reduction through material efficiency and recycling initiatives, and using 3D printing technology empower businesses by bringing their ideas to life quickly while optimizing manufacturing processes. At Taloshub we are absolutely dedicated to delivering exquisite quality, precision, and customer satisfaction – always.

At Taloshub we place a high priority on continuously improving and optimizing our 3D printing processes in order to maintain the utmost standards for quality and precision. Our proficient team of technicians and engineers are diligent in monitoring each step of our printing process.

From file preparation to post processing. Ensuring that we achieve exceptional results. Here are some technical specifications outlining key details for each of our 3D printing methods:

For FDM:

– Minimum wall thickness: 0.8 mm

– Layer height: 100 – 300 μm

– Maximum build size: 500 x 500 x 500 mm

– Tolerances: ±0.5%, lower limit ±0.5 mm (±0.020″)

With SLA:

– Minimum wall thickness: 0.5 mm

– Layer height: 50 -100 μm

– Maximum build size:145 x145 x175 mm

– Tolerances: ±0.5%, lower limit ±0.15mm (±0.006″)

Using SLS:

– Minimum wall thickness: 0.7 mm

-Layer height:100μm

-Maximum build size:420x500x420mm

-Tolerances:+/-0.3%, lower limit+/-0.3mm (±0.012″)

And finally with MJF:

-Minimum wall thickness : o,.7mm

-Layer Height 80 um

-Max Build Size 380x285x380mm

-Tolerance:+/- o,..3 % , Lower Limit +/- o. .. 3rrim( +/-o.o12″)

At Taloshub we have an unwavering commitment to excellence that extends far beyond the technical aspects. We also hold steadfast values when it comes to sustainability and eco conscious practices. To ensure a responsible approach to manufacturing. We make every effort to minimize waste through efficient material usage and recycling initiatives. Our expertise in harnessing the power of 3D printing technology allows us to empower businesses by bringing their ideas to life accelerating product development and optimizing their manufacturing processes. At Taloshub. We are absolutely dedicated to delivering exquisite quality, precision, and customer satisfaction.